Our Clients

At DASH Engineering, we understand the critical role conveyor pulleys play in your mining operations. Unfortunately, standard conveyor pulley bearings are plagued by a common enemy: contamination. These failures, often caused by "dirt and water" ingress, result in costly downtime and lost production.The Problem: Ineffective Seals and Unpredictable FailuresTraditional labyrinth and "Taconite Seals" developed in the 1960s simply haven't kept pace with modern demands. These grease-filled labyrinths offer minimal protection against contamination and "multi barrier ideas" combining labyrinth seals with stagnant grease can actually worsen the issue, promoting contamination migration.

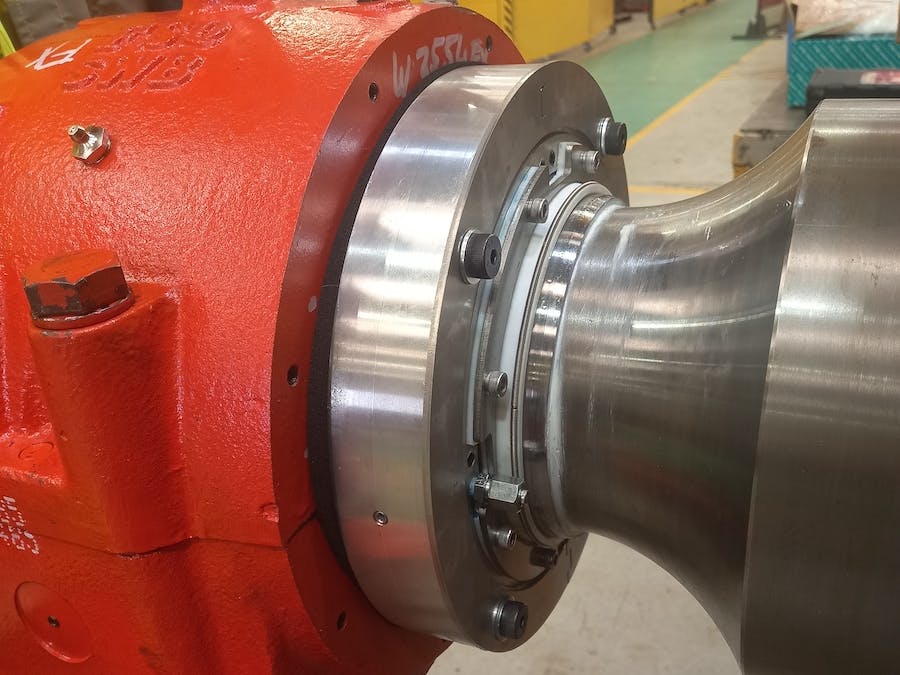

Introducing the SAPO® Seal: A Smarter SolutionThe patented SAPO® Seal represents a breakthrough in conveyor pulley bearing reliability. This innovative design addresses the limitations of traditional seals by offering:

- Superior Contamination Protection: The SAPO® Seal effectively blocks the ingress of dirt and water, extending bearing life and reducing downtime.

- Accommodates Misalignment: Unlike all forms of labyrinth seals, the SAPO® Seal adapts to inherent misalignment

- Axial Float Capability: The design allows for axial movement of the bearing, a critical factor in conveyor pulley applications.

- Monitorability & Maintainability: The SAPO® Seal utilises a pressurised closed-oil system for easy monitoring, flushing and oil changes while operational. An endoscope camera can also be integrated to visually verify seal effectiveness.

The Benefits of Switching to SAPO® Seals

By implementing the SAPO® Seal, you can expect:

- Reduced Downtime: Minimise unexpected bearing failures and keep your operations running smoothly.

- Extended Equipment Life: The SAPO® Seal protects bearings, reducing replacements and maintenance costs.

- Improved Efficiency: Optimised bearing performance translates to increased production output.

- Enhanced Safety: Reduced risk of catastrophic bearing failures promotes a safer work environment.

Learn More About the SAPO® Seal

Contact DASH Engineering today to discuss how the SAPO® Seal can revolutionise your conveyor pulley reliability and optimise your mining operations.Ready to delve deeper?Click the button below to visit the SAPO® Seal website for comprehensive information and technical specifications.

Visit SAPO® Seal Website

Contact Us

Call or email us today or leave us a message and we'll get back to you soon!